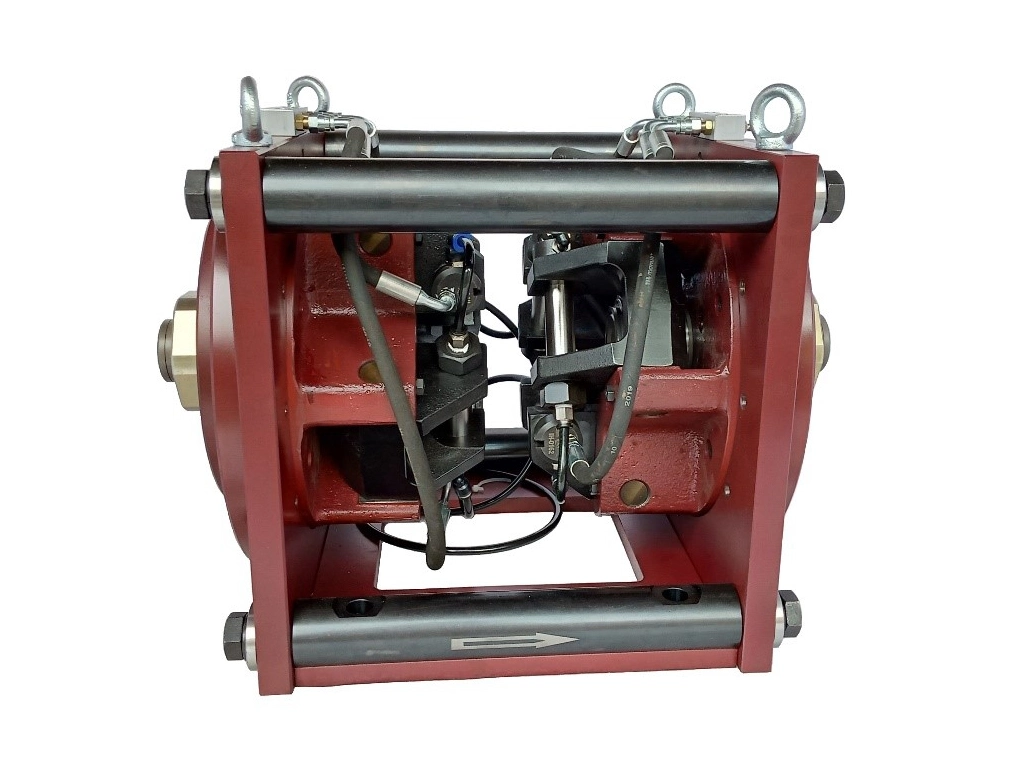

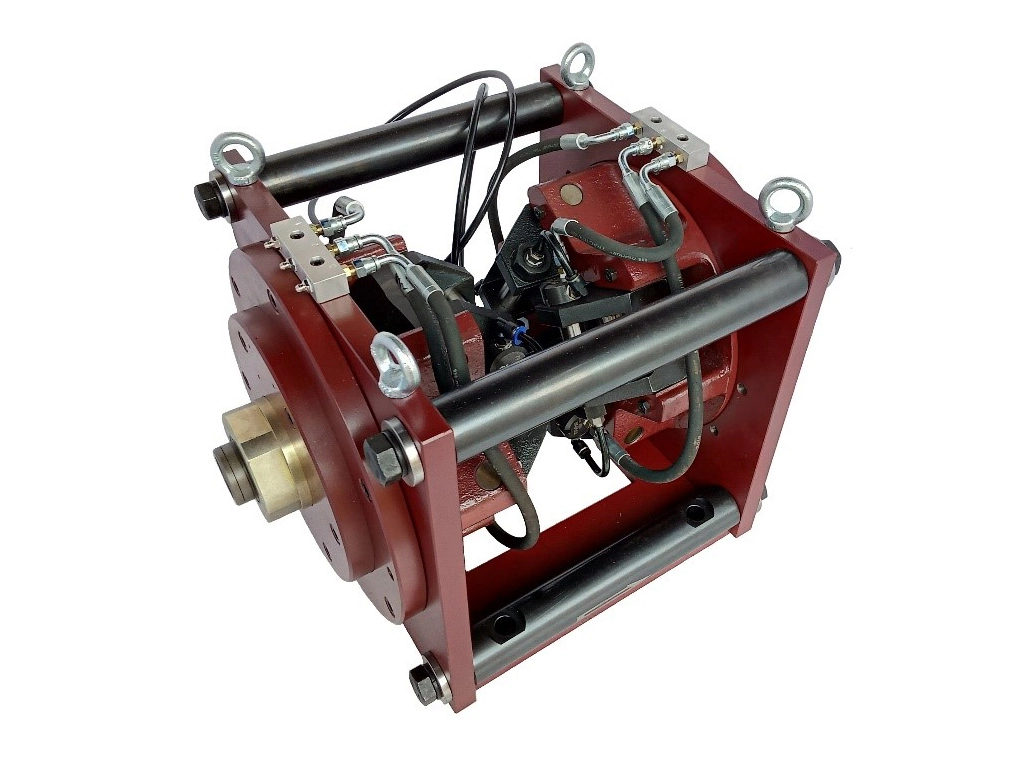

Our precision-engineered cold rolling cassette system is designed to manufacture profiled wires of various geometries, meeting stringent International Standards. The system’s body structure and working mechanism are meticulously crafted for effortless operation and routine services and maintenance procedures. The innovative design of the greasing and water-cooling system ensures consistent performance, maximizing output efficiency. Our system seamlessly integrates with renowned high-speed cold rolling lines, allowing for adaptability across different brands.

| FINISH WIRE RANGE Φ mm | OD Φ mm | ID Φ mm | T mm |

| 4.0 – 9.0 | 125 | 82 | 15 |

| 9.5 – 13.0 | 125 | 82 | 20 |

| 4.0 – 9.0 | 140 | 90 | 15 |

| 9.5 – 13.0 | 140 | 90 | 20 |

| 4.0 – 9.0 | 150 | 90 | 15 |

| 9.5 – 13.0 | 150 | 90 | 20 |

Note: Size customization can be considered upon request

(consist of PR, PR engraved with alphabet & numeric, PR engraved with dots, RO, RT & FO)

PR

PR engraved with alphabet & numeric

PR engraved with dots

RO

RT

FO

Roll Holder

| Wire Rod (mm) |

Oval Reducing |

Round Reducing |

Oval Reducing |

Sizing | Outlet Smooth Wire (mm) |

| 5.5 | RO 1 | RT 1 | RO 0 | CA 4.0 | 4.0 |

| RO 1 | RT 1 | RO 1 | CA 4.5 | 4.5 | |

| 6.0 - 7.0 | RO 2 | RT 2 | RO 1 | CA 5.0 | 5.0 |

| RO 2 | RT 2 | RO 1 | CA 5.5 | 5.5 | |

| 7.5 | RO 3 | RT 3 | RO 2 | CA 6.0 | 6.0 |

| RO 3 | RT 3 | RO 2 | CA 6.5 | 6.5 | |

| 8.5 | RO 4 | RT 4 | RO 3 | CA 7.0 | 7.0 |

| RO 4 | RT 4 | RO 3 | CA 7.5 | 7.5 | |

| 10.0 - 11.0 | RO 5 * | RT 5 * | RO 4 | CA 8.0 | 8.0 |

| RO 5 * | RT 5 * | RO 4 | CA 8.5 | 8.5 | |

| 12.0 | RO 6 * | RT 6 * | RO 5 * | CA 9.0 | 9.0 |

| RO 6 * | RT 6 * | RO 5 * | CA 9.5 * | 9.5 | |

| RO 6 * | RT 6 * | RO 5 * | CA 10.0 * | 10.0 | |

| RO 6 * | RT 6 * | RO 5 * | CA 10.5 * | 10.5 | |

| 14.0 | RO 7 * | RT 7 * | RO 6 * | CA 11.0 * | 11.0 |

| RO 7 * | RT 7 * | RO 6 * | CA 11.5 * | 11.5 | |

| RO 7 * | RT 7 * | RO 6 * | CA 12.0 * | 12.0 |

* Rolls in blue bold have a thickness of 20mm

| Wire Rod (mm) |

Oval Reducing |

Round Reducing |

Forming | Profiling | Outlet Ribbed Wire (mm) |

| 5.5 | RO 1 | RT 1 | FO 1 | PR 4.0 | 4.0 |

| RO 1 | RT 1 | FO 1 | PR 4.5 | 4.5 | |

| 6.0 - 7.0 | RO 2 | RT 2 | FO 1 | PR 5.0 | 5.0 |

| RO 2 | RT 2 | FO 1 | PR 5.5 | 5.5 | |

| 7.5 | RO 3 | RT 3 | FO 2 | PR 6.0 | 6.0 |

| RO 3 | RT 3 | FO 2 | PR 6.5 | 6.5 | |

| 8.5 | RO 3 | RT 3 | FO 2 | PR 7.0 | 7.0 |

| 9.0 | RO 4 | RT 4 | FO 3 | PR 7.5 | 7.5 |

| 10.0 - 11.0 | RO 5 * | RT 5 * | FO 3 | PR 8.0 | 8.0 |

| RO 5 * | RT 5 * | FO 3 | PR 8.5 | 8.5 | |

| RO 5 * | RT 5 * | FO 3 | PR 9.0 | 9.0 | |

| 12.0 - 13.0 | RO 6 * | RT 6 * | FO 4 * | PR 9.5 * | 9.5 |

| RO 6 * | RT 6 * | FO 4 * | PR 10.0 * | 10.0 | |

| RO 6 * | RT 6 * | FO 4 * | PR 10.5 * | 10.5 | |

| 14.0 | RO 7 * | RT 7 * | FO 4 * | PR 11.0 * | 11.0 |

| RO 7 * | RT 7 * | FO 4 * | PR 11.5 * | 11.5 | |

| RO 7 * | RT 7 * | FO 4 * | PR 12.0 * | 12.0 |

* Rolls in blue bold have a thickness of 20mm

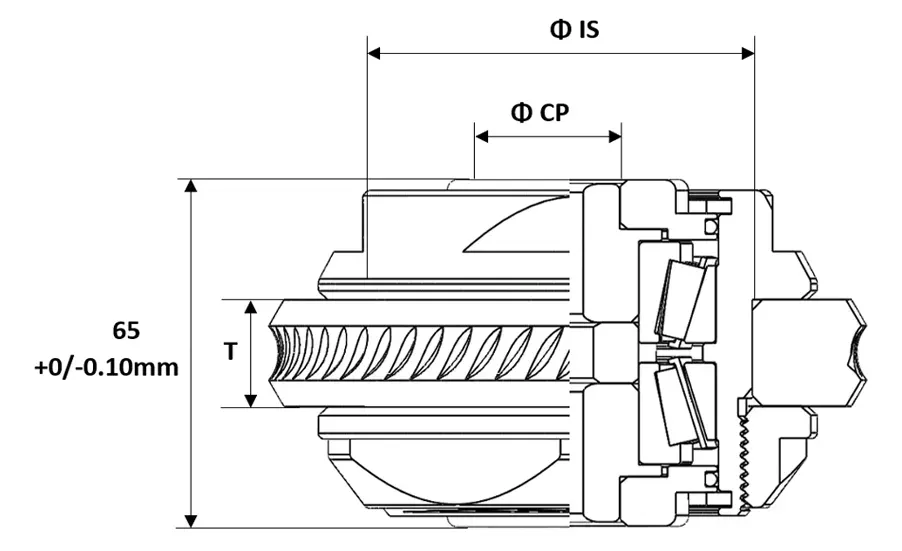

| INSIDE ROLL (IS) Φ mm | ROLL THICKNESS (T) mm | COOLING PIN (CP) Φ mm |

| 82 | 15 | 25 |

| 82 | 20 | 25 |

| 82 | 15 | 26 |

| 82 | 20 | 26 |

| 90 | 15 | 30 |

| 90 | 20 | 30 |

There are simpler way for us to get in touch and answer your question